Abstract

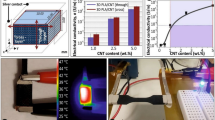

Positive temperature coefficient (PTC) composites have received significant attention as electronic applications such as resettable fuses, safe batteries, self-regulating heating device and temperature sensors. Despite PTC composites preferred to industrial applications due to their easy processing, low density, good flexibility, and toughness, but poor reproducibility due to the conductive network randomly deconstructing or reconstructing in the molten state of polymer matrix delays the practical application. In particular, PTC intensity and reproducibility are important factors for application to temperature sensors. Herein, we present ethylene–vinyl acetate (EVA)-based PTC composites that demonstrate an enhanced intensity and reproducibility by controlling filler mobility and thermal expansion via combination of 0-D and 2-D carbon filler. A Carbon black (CB)/Exfoliated graphite (ExG)/EVA composite exhibited the high PTC intensity and superior reproducibility at repeated thermocycles. Furthermore, the CB/ExG/EVA composites exhibited a temperature sensitivity of approximately 14 times higher than that reported in another temperature sensor literature. The formation and inhibition of conducting networks on the controlled filler combination exhibited the synergistic effects of the 0-D and 2-D carbon fillers. The PTC composite with combination of 0-D and 2-D fillers can detect human skin temperature through real-time monitoring and showed an accuracy of 0.41 °C. This work provides a feasibility of PTC temperature sensor in specific applications that require relatively high temperature sensitivity and flexibility, such as monitoring the human body temperature.

Graphical abstract

Similar content being viewed by others

References

Chun KY, Oh Y, Rho J et al (2010) Highly conductive, printable and stretchable composite films of carbon nanotubes and silver. Nat Nanotechnol 5:853–857. https://doi.org/10.1038/nnano.2010.232

Hansen TS, West K, Hassager O, Larsen NB (2007) Highly stretchable and conductive polymer material made from poly(3,4-ethylenedioxythiophene) and polyurethane elastomers. Adv Func Mater 17:3069–3073. https://doi.org/10.1002/adfm.200601243

Stankovich S, Dikin DA, Dommett GH et al (2006) Graphene-based composite materials. Nature 442:282–286. https://doi.org/10.1038/nature04969

Kim KS, Zhao Y, Jang H et al (2009) Large-scale pattern growth of graphene films for stretchable transparent electrodes. Nature 457:706–710. https://doi.org/10.1038/nature07719

Gu H, Guo J, Wei H et al (2015) Strengthened magnetoresistive epoxy nanocomposite papers derived from synergistic nanomagnetite-carbon nanofiber nanohybrids. Adv Mater 27:6277–6282. https://doi.org/10.1002/adma.201501728

Hu Y, Chen W, Lu L, Liu J, Chang C (2010) Electromechanical actuation with controllable motion based on a single-walled carbon nanotube and natural biopolymer composite. ACS Nano 4:3498–3502. https://doi.org/10.1021/nn1006013

Xu Z, Wang N, Li N et al (2016) Liquid sensing behaviors of conductive polypropylene composites containing hybrid fillers of carbon fiber and carbon black. Compos Part B Eng 94:45–51. https://doi.org/10.1016/j.compositesb.2016.03.047

Mamunya Y, Matzui L, Vovchenko L et al (2019) Influence of conductive nano- and microfiller distribution on electrical conductivity and EMI shielding properties of polymer/carbon composites. Compos Sci Technol 170:51–59. https://doi.org/10.1016/j.compscitech.2018.11.037

Bao SP, Liang GD, Tjong SC (2011) Effect of mechanical stretching on electrical conductivity and positive temperature coefficient characteristics of poly(vinylidene fluoride)/carbon nanofiber composites prepared by non-solvent precipitation. Carbon 49:1758–1768. https://doi.org/10.1016/j.carbon.2010.12.062

Deng H, Skipa T, Bilotti E et al (2010) Preparation of high-performance conductive polymer fibers through morphological control of networks formed by nanofillers. Adv Func Mater 20:1424–1432. https://doi.org/10.1002/adfm.200902207

Chu K, Lee SC, Lee S, Kim D, Moon C, Park SH (2015) Smart conducting polymer composites having zero temperature coefficient of resistance. Nanoscale 7:471–478. https://doi.org/10.1039/c4nr04489d

Rybak A, Boiteux G, Melis F, Seytre G (2010) Conductive polymer composites based on metallic nanofiller as smart materials for current limiting devices. Compos Sci Technol 70:410–416. https://doi.org/10.1016/j.compscitech.2009.11.019

Liu Y, Zhang H, Porwal H et al (2017) Universal control on pyroresistive behavior of flexible self-regulating heating devices. Adv Func Mater 27:1702253. https://doi.org/10.1002/adfm.201702253

Zha J-W, Wu D-H, Yang Y, Wu Y-H, Li RKY, Dang Z-M (2017) Enhanced positive temperature coefficient behavior of the high-density polyethylene composites with multi-dimensional carbon fillers and their use for temperature-sensing resistors. RSC Adv 7:11338–11344. https://doi.org/10.1039/c6ra27367j

Xu HP, Wu YH, Yang DD, Wang JR, Xie HQ (2011) Study on theories and influence factors of PTC property in polymer-based conductive composites. Rev Adv Mater Sci 27:173–183

Bao SP, Liang GD, Tjong SC (2009) Positive temperature coefficient effect of polypropylene/carbon nanotube/montmorillonite hybrid nanocomposites. IEEE Trans Nanotechnol 8:729. https://doi.org/10.1109/tnano.2009.2023650

Yi X-S, Shen L, Pan Y (2001) Thermal volume expansion in polymeric PTC composites: a theoretical approach. Compos Sci Technol 61:949–956. https://doi.org/10.1016/S0266-3538(00)00191-3

Park S-J, Kim H-C, Kim H-Y (2002) Roles of work of adhesion between carbon blacks and thermoplastic polymers on electrical properties of composites. J Colloid Interface Sci 255:145. https://doi.org/10.1006/jcis.2002.8481

Bystrov VS, Bdikin IK, Silibin MV et al (2019) Pyroelectric properties of ferroelectric composites based on polyvinylidene fluoride (PVDF) with graphene and graphene oxide. Ferroelectrics 541:17–24. https://doi.org/10.1080/00150193.2019.1574637

Li G, Hu C, Zhai W et al (2016) Particle size induced tunable positive temperature coefficient characteristics in electrically conductive carbon nanotubes/polypropylene composites. Mater Lett 182:314–317. https://doi.org/10.1016/j.matlet.2016.07.020

Zhang P, Wang B-b (2018) Positive temperature coefficient effect and mechanism of compatible LLDPE/HDPE composites doping conductive graphite powders. J Appl Polym Sci 135:46453. https://doi.org/10.1002/app.46453

Li J, Chang C, Li X, Li Y, Guan G (2019) A new thermal controlling material with positive temperature coefficient for body warming: preparation and characterization. Materials 12:1758. https://doi.org/10.3390/ma12111758

Shen L, Lou ZD, Qian YJ (2007) Effects of thermal volume expansion on positive temperature coefficient effect for carbon black filled polymer composites. J Polym Sci Part B Polym Phys 45:3078–3083. https://doi.org/10.1002/polb.21307

Zhang X, Zheng S, Zheng X, Liu Z, Yang W, Yang M (2016) Distinct positive temperature coefficient effect of polymer-carbon fiber composites evaluated in terms of polymer absorption on fiber surface. Phys Chem Chem Phys 18:8081–8087. https://doi.org/10.1039/c6cp00398b

Nakano H, Shimizu K, Takahashi S, Kono A, Ougizawa T, Horibe H (2012) Resistivity–temperature characteristics of filler-dispersed polymer composites. Polymer 53:6112–6117. https://doi.org/10.1016/j.polymer.2012.10.046

Ryu SH, Kim S, Kwon YT et al (2019) Decorating surface charge of graphite nanoplate using an electrostatic coupling agent for 3-dimensional polymer nanocomposite. J Appl Polym Sci 137:48390. https://doi.org/10.1002/app.48390

Ren D, Zheng S, Huang S, Liu Z, Yang M (2013) Effect of the carbon black structure on the stability and efficiency of the conductive network in polyethylene composites. J Appl Polym Sci 129:3382–3389. https://doi.org/10.1002/app.38606

Sun C, Zhao W, Chen S (2008) Studies on the comprehensive performance of graphite and additives filled high density polyethylene composites. J Appl Polym Sci 107:4000–4004. https://doi.org/10.1002/app.27480

Fang Y, Zhao J, Zha J-W, Wang D-R, Dang Z-M (2012) Improved stability of volume resistivity in carbon black/ethylene-vinyl acetate copolymer composites by employing multi-walled carbon nanotubes as second filler. Polymer 53:4871–4878. https://doi.org/10.1016/j.polymer.2012.08.035

Kalaitzidou K, Fukushima H, Drzal LT (2007) Multifunctional polypropylene composites produced by incorporation of exfoliated graphite nanoplatelets. Carbon 45:1446–1452. https://doi.org/10.1016/j.carbon.2007.03.029

Li Q, Kim NH, Yoo G-H, Lee JH (2009) Positive temperature coefficient characteristic and structure of graphite nanofibers reinforced high density polyethylene/carbon black nanocomposites. Compos Part B Eng 40:218–224. https://doi.org/10.1016/j.compositesb.2008.11.002

Wang M, Jamal R, Wang Y, Yang L, Liu F, Abdiryim T (2015) Functionalization of graphene oxide and its composite with poly(3,4-ethylenedioxythiophene) as electrode material for supercapacitors. Nanoscale Res Lett 10:370. https://doi.org/10.1186/s11671-015-1078-x

Prashantha K, Lee JH (2011) Positive temperature coefficient characteristics of multi-walled carbon nanotube filled polyvinylidene fluoride nanocomposites. J Macromol Sci Part A 48:737–741. https://doi.org/10.1080/10601325.2011.596056

Liang J-Z (2019) Electrical conductivities of high-density polyethylene composites reinforced with carbon fiber and nanometer carbon black. Polym Compos 40:E1801–E1807. https://doi.org/10.1002/pc.25166

Stauffer D, Aharony A (2018) Introduction to percolation theory. Taylor & Francis, Milton Park

Ohe K, Naito Y (1971) A new resistor having an anomalously large positive temperature coefficient. Jpn J Appl Phys 10:99–108. https://doi.org/10.1143/jjap.10.99

Chan C-M, Cheng C-L, Yuen MMF (1997) Electrical properties of polymer composites prepared by sintering a mixture of carbon black and ultra-high molecular weight polyethylene powder. Polym Eng Sci 37:1127–1136. https://doi.org/10.1002/pen.11757

Zhang C, Ma C-A, Wang P, Sumita M (2005) Temperature dependence of electrical resistivity for carbon black filled ultra-high molecular weight polyethylene composites prepared by hot compaction. Carbon 43:2544–2553. https://doi.org/10.1016/j.carbon.2005.05.006

Seo M-K, Rhee K-Y, Park S-J (2011) Influence of electro-beam irradiation on PTC/NTC behaviors of carbon blacks/HDPE conducting polymer composites. Current Appl Phys 11:428–433. https://doi.org/10.1016/j.cap.2010.08.013

Shih WP, Tsao LC, Lee CW et al (2010) Flexible temperature sensor array based on a graphite-polydimethylsiloxane composite. Sens (Basel) 10:3597–3610. https://doi.org/10.3390/s100403597

Kaur A, Singh RC (2019) Temperature sensor based on exfoliated graphene sheets produced by microwave assisted freezing induced volumetric expansion of carbonated water. J Mater Sci Mater Electron 30:5791–5807. https://doi.org/10.1007/s10854-019-00878-0

Meyer J (1974) Stability of polymer composites as positive-temperature-coefficient resistors. Polym Eng Sci 14:706–716. https://doi.org/10.1002/pen.760141009

Karimov KS, Khalid F, Chani M et al (2012) Carbon nanotubes based flexible temperature sensors. Optoelectron Adv Mater Rapid Commun 6:194–196

Dankoco M, Tesfay G, Bènevent E, Bendahan M (2016) Temperature sensor realized by inkjet printing process on flexible substrate. Mater Sci Eng B 205:1–5

Sehrawat P, Islam S, Mishra P, Khanuja M (2018) A multi-prong approach towards the development of high performance Temperature sensor using MWCNTs/Al2O3 composite film. Mater Res Bull 99:1–9

Cen-Puc M, Pool G, Oliva-Avilés AI, May-Pat A, Avilés F (2017) Experimental investigation of the thermoresistive response of multiwall carbon nanotube/polysulfone composites under heating-cooling cycles. Compos Sci Technol 151:34–43. https://doi.org/10.1016/j.compscitech.2017.08.003

Trung TQ, Ramasundaram S, Hwang BU, Lee NE (2016) An all-elastomeric transparent and stretchable temperature sensor for body-attachable wearable electronics. Adv Mater 28:502–509. https://doi.org/10.1002/adma.201504441

Annabestani M, Esmaeili-Dokht P, Fardmanesh M (2020) A novel, low cost, and accessible method for rapid fabrication of the modifiable microfluidic devices. Sci Rep 10:16513. https://doi.org/10.1038/s41598-020-73535-w

Osman AF, Alakrach AM, Kalo H, Azmi WNW, Hashim F (2015) In vitro biostability and biocompatibility of ethyl vinyl acetate (EVA) nanocomposites for biomedical applications. RSC Adv 5:31485–31495. https://doi.org/10.1039/C4RA15116J

Schneider C, Langer R, Loveday D, Hair D (2017) Applications of ethylene vinyl acetate copolymers (EVA) in drug delivery systems. J Controll Release 262:284–295. https://doi.org/10.1016/j.jconrel.2017.08.004

Jeon J, Lee HB, Bao Z (2013) Flexible wireless temperature sensors based on Ni microparticle-filled binary polymer composites. Adv Mater 25:850–855. https://doi.org/10.1002/adma.201204082

Yang J, Wei D, Tang L et al (2015) Wearable temperature sensor based on graphene nanowalls. RSC Adv 5:25609–25615. https://doi.org/10.1039/c5ra00871a

Acknowledgements

This work was supported by the National Research Foundation of Korea (NRF) grant funded by the Korea government (MSIT) (No. 2015R1A5A1037548). This research was supported by Future Materials Discovery Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Science, ICT & Future Planning (NRF-2019M3D1A2104158). This research was supported by R&BD Program through the INNOPOLIS funded by Ministry of Science and ICT (2020-IT-RD-0139).

Author information

Authors and Affiliations

Contributions

G.M.G. conceived the experiments and prepared the manuscript. Y.S., S.P., M.L., B.J., and J.P. helped in performing analysis. H.B.C. discussed the results and contributed toward editing the manuscript. Y.H.C. contributed to this manuscript, accepted responsibility for the conducted research, and provided final approval. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing financial interest.

Additional information

Handling Editor: M. Grant Norton.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Go, GM., Park, S., Lim, M. et al. Enhanced positive temperature coefficient intensity and reproducibility with synergistic effect of 0-D and 2-D filler composites. J Mater Sci 57, 18037–18050 (2022). https://doi.org/10.1007/s10853-022-07317-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-022-07317-2